The DECC Company maintains a 10,000 square foot R&D department that duplicates all of DECC’s high-volume production application methods, but on a miniature scale. DECC’s R&D department is a vital asset to our company for numerous reasons.

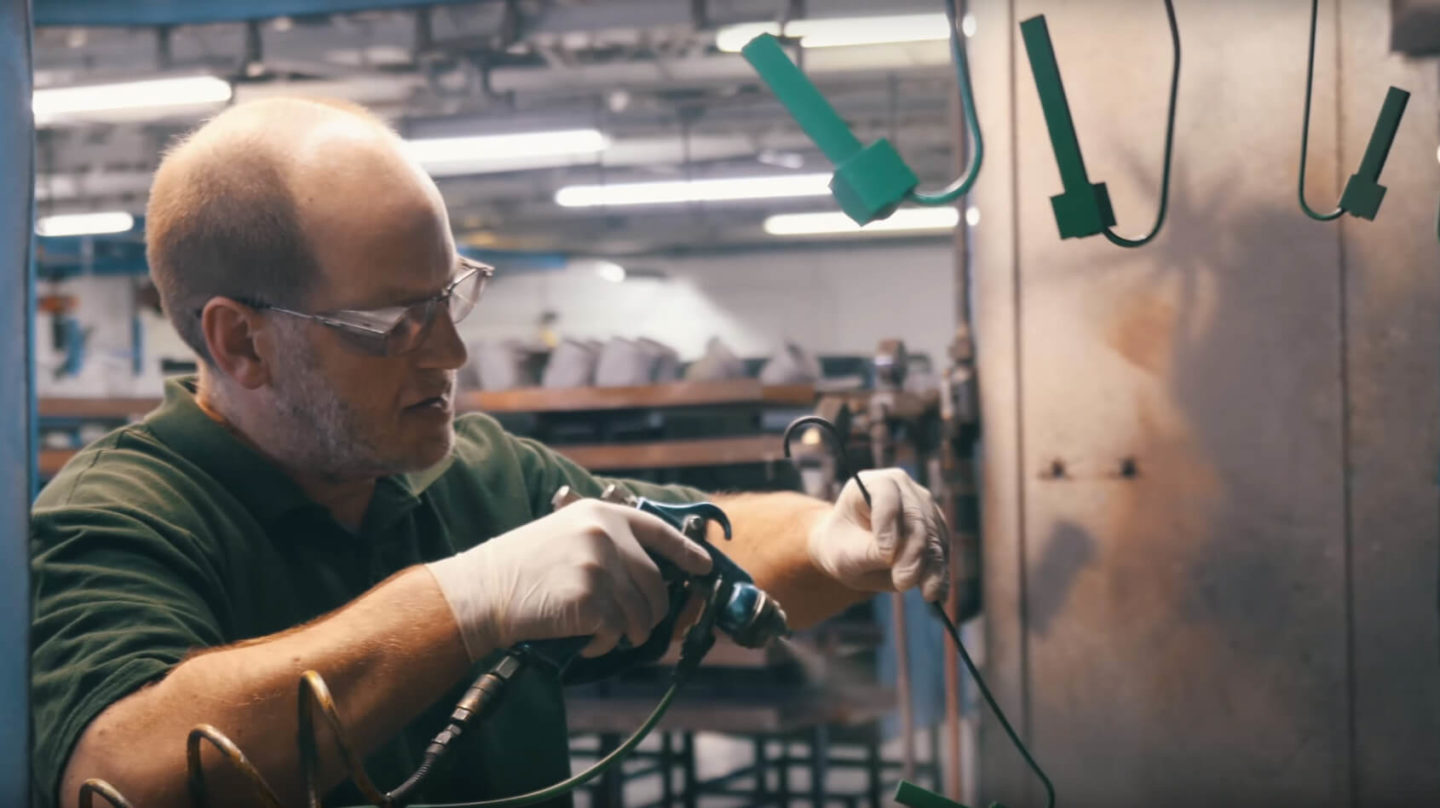

Sample Processing

Because it can be difficult to break into normal production schedules on short notice, our R&D department provides us a means to turn high quality samples quickly and efficiently, allowing our customers get parts on test as soon as possible and giving them a leg up on their competition.

New Coating Validation

As much as many coating resin systems are the same in nature, they are also all a little different. Our R&D spray personnel have over 50 years of combined spraying experience and understand subtle variations in coating spray behavior. By having the ability and knowledge to spray unfamiliar coatings in an R&D environment to determine wet-out characteristics, DECC can hit the ground running on production volumes for an application with an unfamiliar coating.

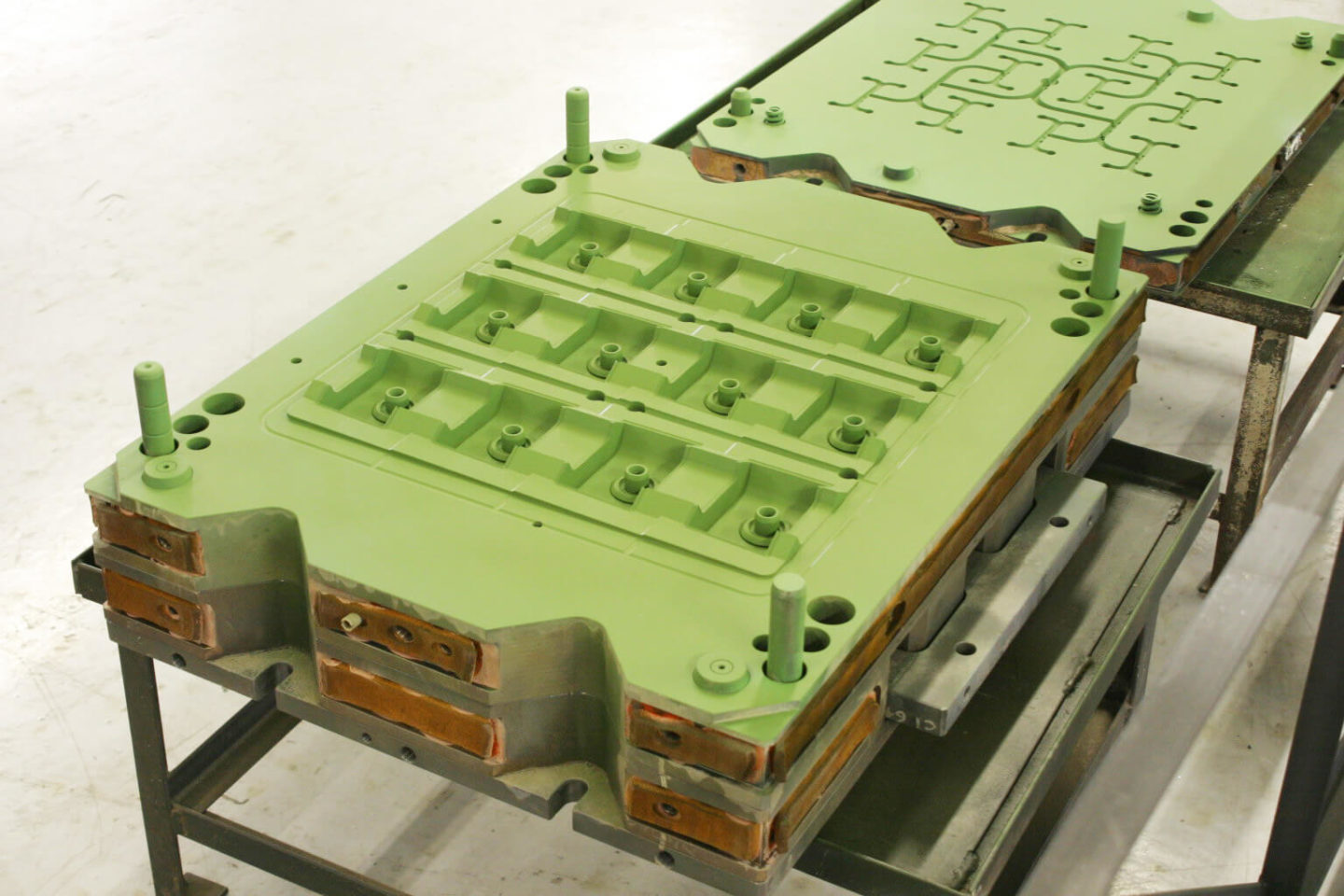

Low Volume & One of a Kind Production

Not every part that DECC coats is high-volume and can be hung on a hook. In our R&D department, we apply coating to plastic injection molds, commercial laundry dryer panels, food production die rollers, 2000lb machinery bases, waffle irons, and an endless variety of larger sized, lower volume components from numerous industries.

Critical Component Performance Production

Sometimes, coating performance is so critical that every production run must be heavily scrutinized and 100% inspected. For instance, DECC applies an adhesive for rubber over-molding to a medical component used in open heart surgery. Even though it is higher volume, this type of production is performed in our R&D department to ensure every part meets the extremely stringent quality standards expected from our customer.

Related Articles

How to Center Your Process in a Coating Application (Here’s a Hint: You Can’t)

In every quality position, in every market, the goal is always the same:...

How a Rack-Spray Process Audits Your Parts

Utilizing a rack-spray coating application for your components as opposed to a dip-spin method has...

The Three C’s: Coverage, Cure & Cross Hatch

Will the coating pass this test or that? Will it reach this many...