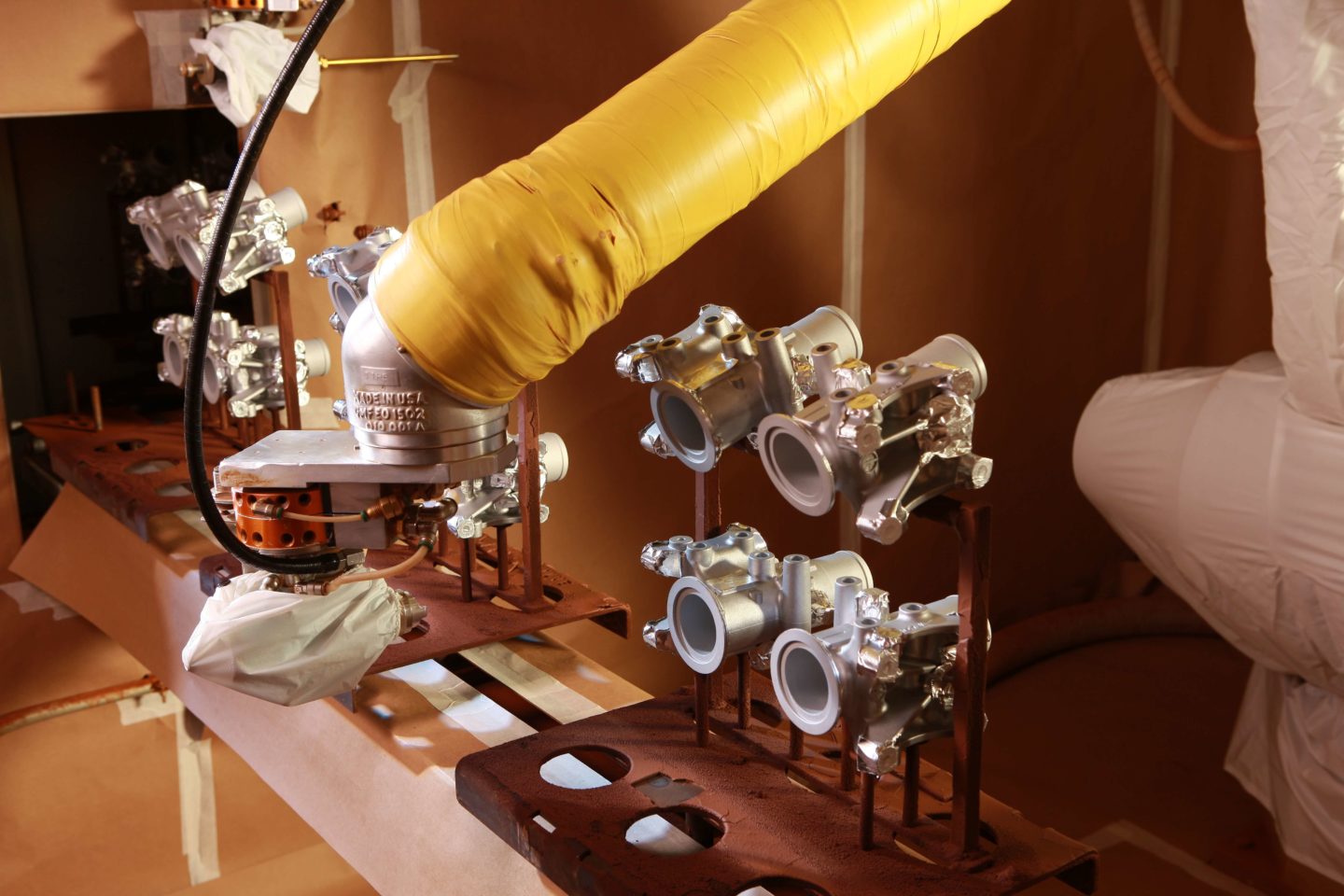

Originally dedicated to aluminum castings and valves in their own isolated production cell, our two six-axis FANUC robots are now stationed on the back end of our electrostatic spray line. With this technology, we are able to coat unique part geometries, including difficult angles, that were originally unsuited for an automated rack-spray coating application.

Fixtures move along a conveyor and in front of our electrostatic bells for their first application of coating. After passing through a flash-off oven, they then enter the robot booths. Each robotic arm sprays the coating in a pattern that has been predetermined by with a part-specific program. The robots utilize HVLP spray guns to help combat the Faraday cage effect and ensure superior coverage and coating uniformity. Also, these robots provide a repeatable, consistent process over the course of millions of parts…something not easily duplicated by a typical hand spray touch-up.

If you have a component with a challenging geometry, DECC will work with your team to create the ideal coating solution for your specific application.

To learn more about our robotic spray coatings, contact DECC today.

Related Articles

Reduce Plastic Sticking with Dryer Panel Coatings

DECC SOLVES PROBLEM OF PLASTIC STICKING TO DRYER PANELS

Coatings for a Quiet Ride

As cars have gotten quieter and quieter over the years, auto makers have...

Dip Spin vs. Rack Spray – Why Not Both?

When it comes to the application of liquid-based functional coatings, there are two...