Since 1984, coated automotive door hinge pins keep E-Coat from stick to them during the E-Coat process, while remaining to have dry film capabilities.

In some automotive assemblies, parts are E-Coated for corrosion protection. However, there are instances where it may be necessary for some of the components to be free of E-Coat. In this instance, DECC can apply a coating to replace the costly masking and un-masking step in this process.

The E-coat resistant coating product insulates the desired portion of the part so the E-coating will not be able to bond to the protected area. For example, in 1984, we helped resolve an E-coat related issue on door pin parts for the Ford Motor Company. Our coating resolution, quality, and on-time delivery have allowed us to continue coating these very same parts to this day.

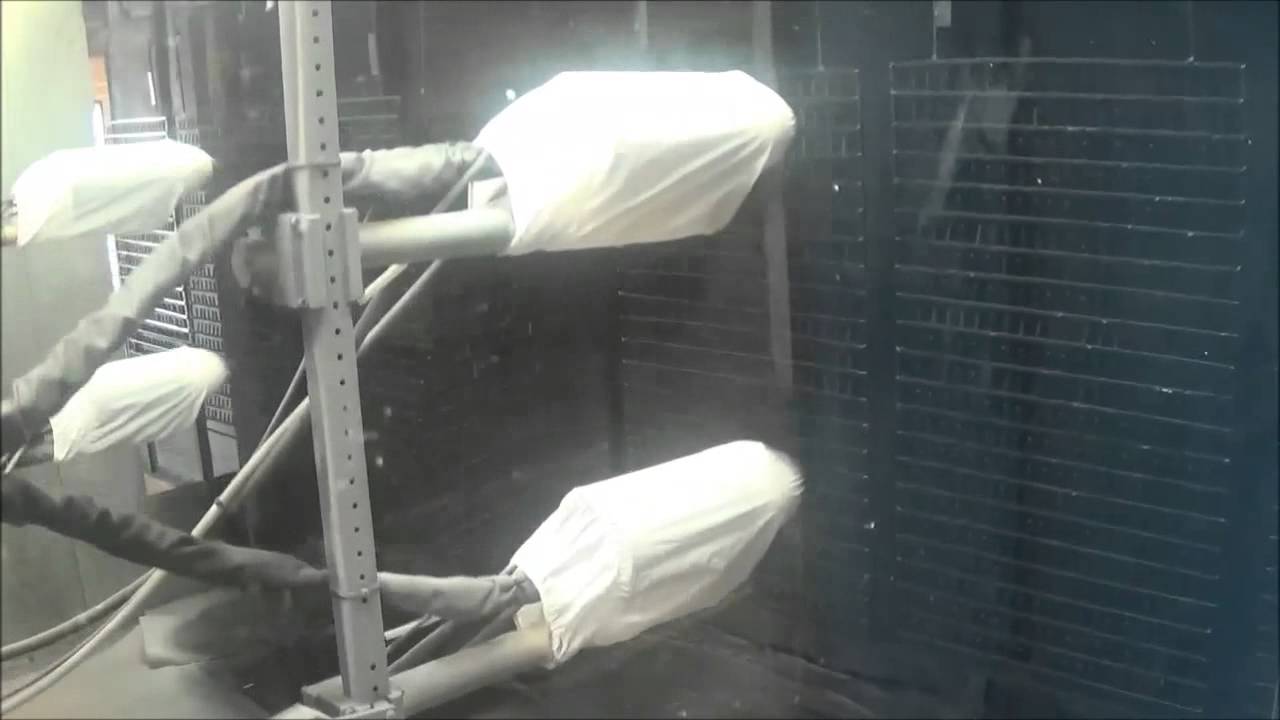

From low volume to high volume, the DECC Company’s engineering and development team can design a fixture that allows E-coat resistant coating to be applied to the critical areas of your part while masking other areas that need to be E-coated.

Contact the DECC Company for help with your E-coat resistance and non-stick coating challenges today.

Related Articles

Reduce Plastic Sticking with Dryer Panel Coatings

DECC SOLVES PROBLEM OF PLASTIC STICKING TO DRYER PANELS

Coatings for a Quiet Ride

As cars have gotten quieter and quieter over the years, auto makers have...

Dip Spin vs. Rack Spray – Why Not Both?

When it comes to the application of liquid-based functional coatings, there are two...