Decc's FDA Acceptable Coating System Options

At The DECC Company, we have narrowed our focus to three FDA acceptable coating application choices to ensure our customers can find a high quality and commercial grade solution to their specific coating challenge.

Please contact us in regards to your FDA coating challenge. With our knowledgeable staff and extensive history of developing creative ways to solve problems, we know we can help find a solution that works best for you.

For more information on Whitford coatings, please visit their site.

Good

Utilizing Xylan 8870, this high cure, fluoropolymer based release coating is stain, wear, abrasion, household chemical and high temperature resistant. Typical applications include heat sealing bars, post or pre-formed cookware and domestic appliances, among many others.

Better

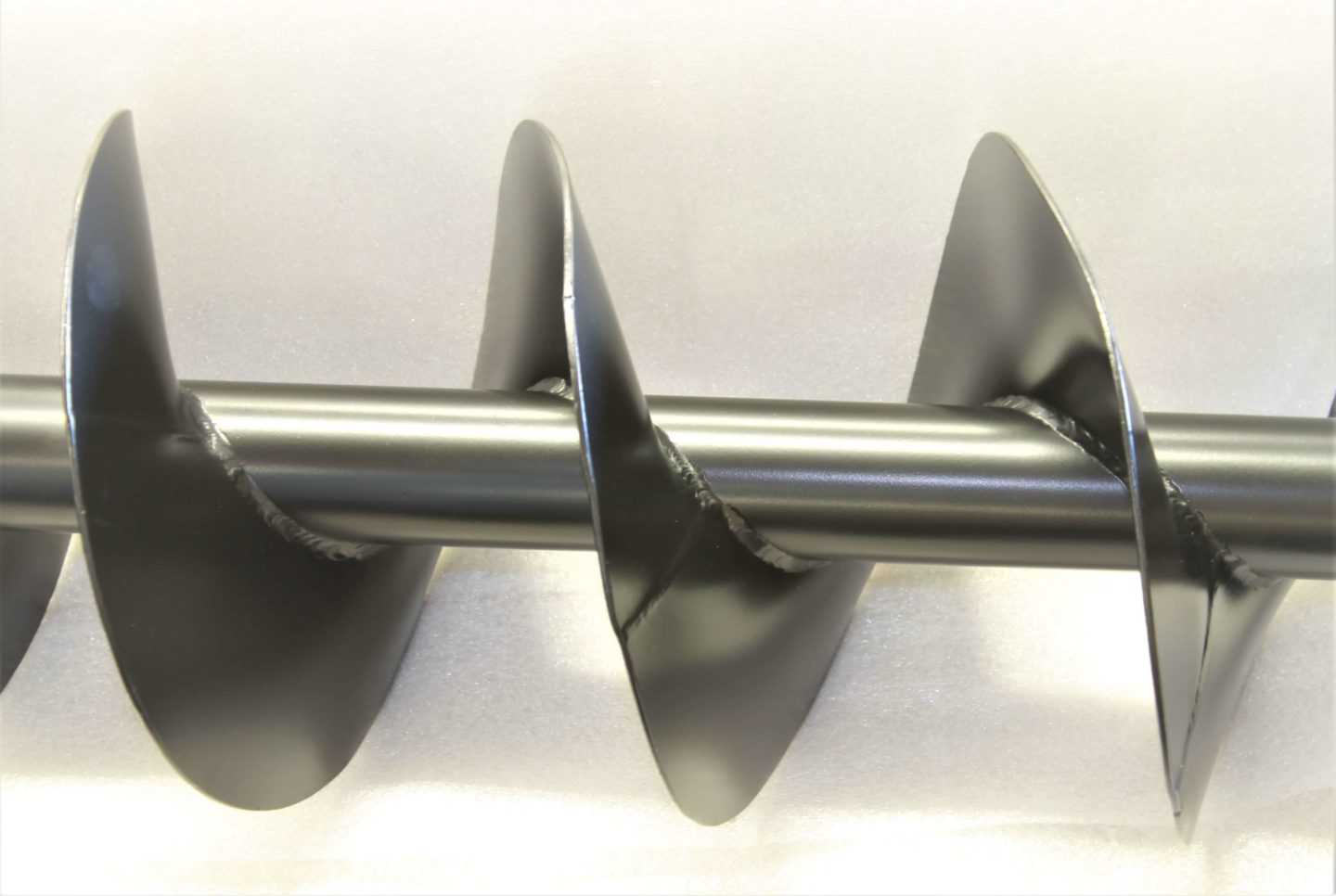

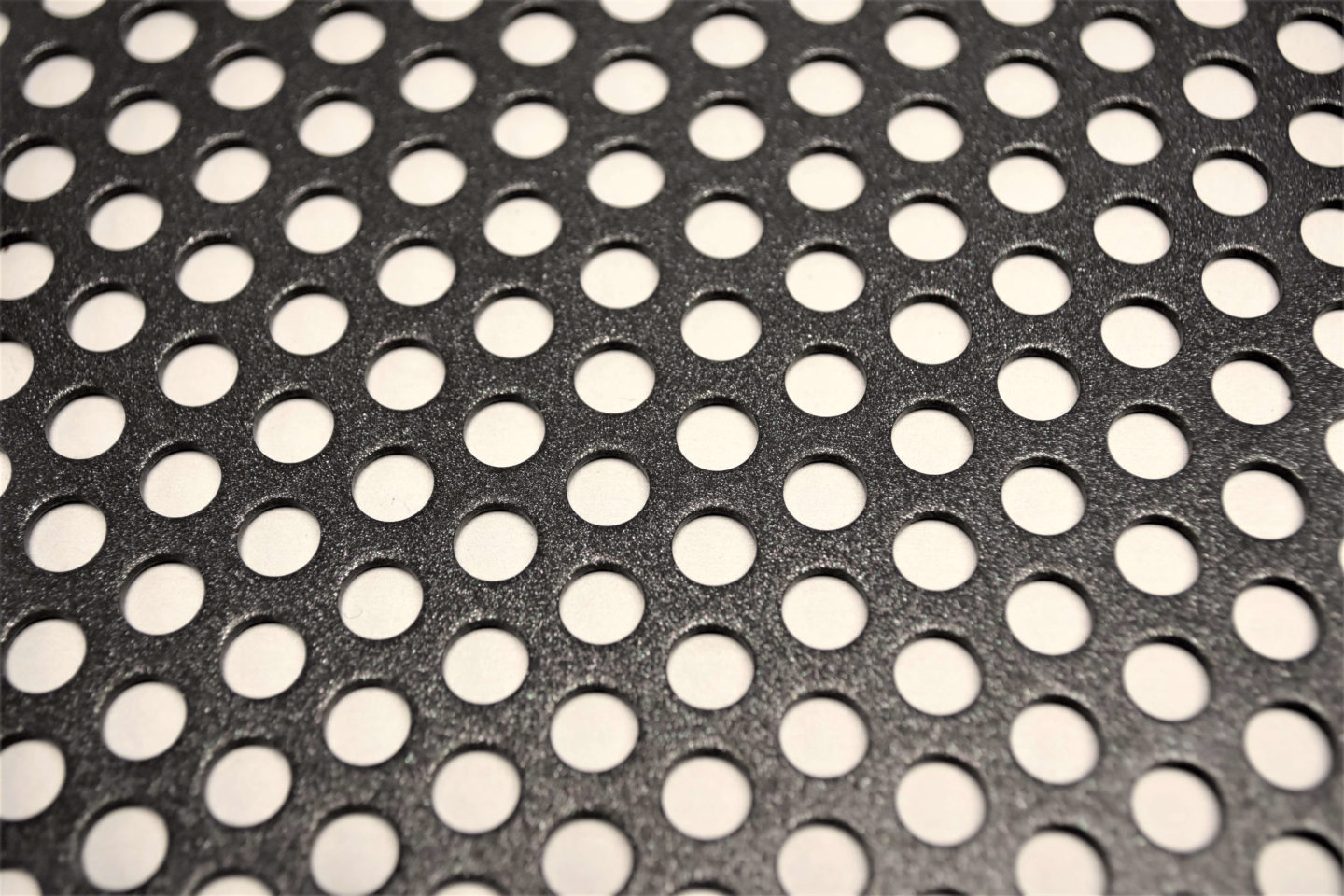

When a durable, greatly lubricious nonstick surface is desired, the combination of the high abrasion and wear resistant primer Xylan 1391 with the excellent release properties of the Xylan 1331 top coat in our two coat system is the better option. While both coatings can be used independently from the other, the combination of the two makes for the best results. The two-coat system is ideal for commercial grade food processing equipment.

Best

If there was ever a coating application that is virtually perfect in every aspect for commercial grade food processing equipment, the Whitford Eclipse system is it. If there was one critique of this application system, it would be that it is TOO good. The primer is dedicated entirely to durability and abrasion resistance with their reinforced resins, increasing the product’s lifecycle substantially. The topcoat is focused solely on release. As long as it can handle a 700-degree bake cycle, this coating application will work on virtually any substrate.

Why Are Coatings Termed “FDA Acceptable” or “FDA Compliant” and Not “FDA Approved”?

The FDA’s (Food & Drug Administration) purpose in the US it to develop and enforce rules and regulations to protect the public in the fields of food, drugs, cosmetics, and medical devices. Before a new drug or medical device is introduced, the manufacturer must demonstrate its efficacy to the FDA and, if it passes, it must be formally approved prior to its use.

However, you may be surprised to learn that the FDA does not have an approval process for nonstick coatings that come into direct contact with food. The FDA does not review the composition of the nonstick coatings before they enter the market, nor do they inspect, test, or approve them. What the FDA does provide is an exhaustive set of regulations which govern the formulation, manufacture, and use of nonstick coatings.

As a result, the onus of compliance to these regulations is placed on the manufacturers of nonstick coatings. Because it is the manufacturer that is responsible for complying with the regulations when producing a coating and not the FDA that approves a coating once it is manufactured, the correct terminology is that a coating is “FDA Compliant” or “FDA Acceptable”, not “FDA Approved.”

Related Articles

Reduce Plastic Sticking with Dryer Panel Coatings

DECC SOLVES PROBLEM OF PLASTIC STICKING TO DRYER PANELS

Coatings for a Quiet Ride

As cars have gotten quieter and quieter over the years, auto makers have...

Dip Spin vs. Rack Spray – Why Not Both?

When it comes to the application of liquid-based functional coatings, there are two...