DECC SOLVES PROBLEM OF PLASTIC STICKING TO DRYER PANELS

By Applying an Abrasion Resistant Release Coating, DECC Helps Commercial Healthcare &

Uniform Laundry Facilities Minimize Maintenance Hassles from Plastic Buildup in Dryers

The DECC Company has been in the commercial laundry market by applying an abrasion resistant release coating to dryer panels, ultimately offering numerous benefits for our

customers.

Primarily useful to facilities that focus on healthcare laundry, the coating DECC applies

drastically reduces the amount of plastic and debris that adheres to the inside of a dryer as

compared to a dryer with uncoated panels. The abrasion resistant qualities of the coating

greatly increase its durability, as well, ensuring extended performance as compared to some other panel treatments that must be redone every seven to eight months.

- DECC’s coating solution for dryer panels:

- Reduces plastic buildup in your dryer

- Substantially decreases down-time due to maintenance and cleaning

- Helps to maintain “like new” dryer efficiency and air flow for an extended period of time

With dryer panels coated by DECC, the need for ice blasting and drilling holes is eliminated. Although routine cleaning of the panels is still required, the time it takes is drastically diminished. Lenny Crosby of West Michigan Shared Laundry stated the following:

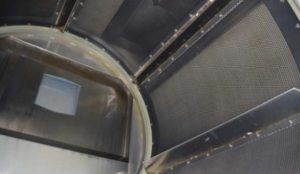

Dryer panel before applying an abrasion resistant release coating.

“It takes almost 10 hours for one of our maintenance guys to clean one dryer panel that has been in service for seven to ten months. With DECC’s coating, we were able to clean three dryer panels in a little over an hour and they had been in service three or four months longer than the uncoated panels.”

“I can’t describe how happy I am with the performance of this coating, I would recommend DECC and their service to anyone in the industry.”

Dryer panel after applying an abrasion resistant release coating.

A dryer with clogged panels can experience a 30-35% increase in drying times or more.

Panels coated by DECC allow for greater efficiency and air flow, as compared to uncoated panels, because it takes far longer for plastic and debris to build inside the dryer. As a result, production capacity is maintained and energy costs are reduced.

As a result of dramatically reduced down-time and labor, combined with increased production capacity and lowered energy costs, the investment of having dryer panels coated by DECC could be returned in a matter of months.

DECC is dedicated to solving customer problems with specialized coating applications and custom services.

Contact Us

If plastic sticking to your dryer panels is an issue in your facility, please reach out to us for a quote on applying our coating recipe.

Contact UsRelated Articles

Coatings for a Quiet Ride

As cars have gotten quieter and quieter over the years, auto makers have...

Dip Spin vs. Rack Spray – Why Not Both?

When it comes to the application of liquid-based functional coatings, there are two...

High-Volume Orders, Small-Volume Orders, and How Changeover Impacts Cost Savings

When a customer asks our team, “How much will this coating application cost?”...