Featured Article

How a Rack-Spray Process Audits Your Parts

Utilizing a rack-spray coating application for your components as opposed to a dip-spin method has many obvious benefits.

Read More

How to Choose the Right Coating Application Method: Part Two

Last week our post detailed the various “soft-touch” coating application methods available in the industry....

Coating Information, Quality Information

How to Choose the Right Coating Application Method: Part One

In terms of functional coatings, there are numerous applications methods that are utilized...

Coating Information, Quality Information

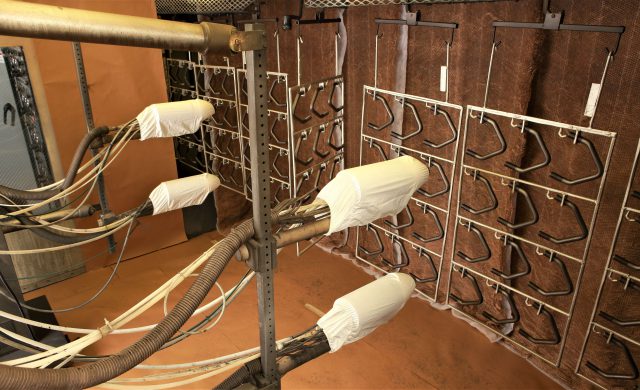

The Rack-Spray, Soft Touch Technology of DECC

The DECC Company is an almost exclusively rack-spray facility. During the coating process, components...

Uncategorized

How to Avoid Setting a New Part Up for Failure

When a manufacturing design engineer is developing a component, they are designing it...

Coating Information, Quality Information

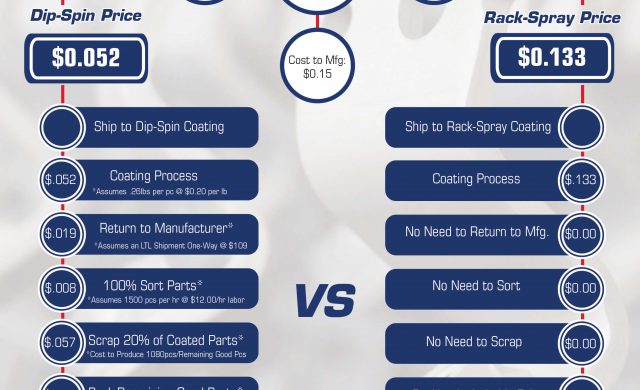

Infographic: The True Cost of Dip-Spin vs Rack-Spray

Simply put: there are part geometries that lend themselves to a dip-spin coating...

Coating Information, Quality Information

The Limitations of Rack-Spray: Unfortunately, it isn’t for all components

The DECC Company’s goal is to be the go-to resource for all of...

Coating Information, Quality Information

Browse by Category

Stay Connected

Follow us.